RFID for Manufacturing

In today’s competitive landscape, industrial enterprises face constant pressure to increase productivity, reduce costs, and optimize operations. One powerful solution to achieve these goals is integrating RFID (Radio Frequency Identification) technology with the Internet of Things (IoT). This combination enables companies to gain real-time visibility into their operations, automate processes, and make data-driven decisions that drive efficiency. As a manufacturer specializing in passive RFID tags, we explore how RFID technology is transforming manufacturing and the direct benefits it offers to industrial enterprises.

How are RFID and IoT Technology Related?

The Internet of Things (IoT) refers to a network of physical devices equipped with sensors, software, and other technologies that enable them to exchange data with other systems over the Internet. This rapidly growing field allows businesses to access, share, and analyze data like never before. The Industrial Internet of Things (IIoT) leverages this technology specifically for industrial applications, enhancing efficiency, productivity, and decision-making across various sectors.

RFID (Radio Frequency Identification) technology is closely intertwined with IIoT. Essentially, RFID acts as an enabler for IoT by transforming everyday objects into “smart” items that are part of the interconnected IoT ecosystem. Through RFID, even traditionally “dumb” assets—such as tools, equipment, or inventory—can become data-generating sources that provide valuable insights.

An RFID system consists of two main components: RFID tags (or labels) and RFID readers. RFID readers use electromagnetic fields to automatically identify and capture information stored in RFID tags attached to objects. Unlike barcodes, which require direct line-of-sight scanning, RFID tags can be read remotely and simultaneously, even if multiple tags are present. Each RFID tag can be equipped with a unique identifier, making it possible to distinguish between individual items effortlessly.

By integrating RFID technology with IIoT, industrial enterprises can collect real-time data on the location, condition, and status of assets and materials, allowing for more efficient asset management, process optimization, and data-driven decision-making.

Benefits of Integrating RFID Technology with Industrial IoT

The integration of RFID technology and Industrial IoT (IIoT) in manufacturing brings numerous potential advantages. These technologies work together to provide greater visibility, accuracy, and efficiency in managing assets and inventory throughout the supply chain. Below are some of the key benefits:

- Real-Time Visibility:

With RFID tags and IIoT-enabled sensors, businesses gain improved real-time visibility into the location and status of assets and inventory items. This continuous tracking helps managers access current data, reduce errors associated with manual tracking, and make more informed decisions regarding inventory management, logistics, and operational planning.

- Increased Accuracy and Automation:

RFID technology facilitates the accurate identification and tracking of individual items without the need for direct human intervention. When combined with IIoT platforms, data collection and processing are largely automated, which can significantly reduce human errors and improve overall accuracy in managing inventory and assets.

- Optimized Operations and Predictive Maintenance:

The use of RFID and IIoT enables businesses to adopt a more proactive approach to maintenance management. By continuously monitoring asset conditions and performance, companies can detect anomalies and potential issues early on, allowing for timely scheduling of maintenance activities. This predictive maintenance approach can help reduce unexpected downtime, extend the lifespan of assets, and lower maintenance costs, thereby enhancing the overall efficiency of industrial operations.

- Enhanced Security and Traceability:

RFID tags equipped with unique identifiers contribute to more secure and traceable asset management by ensuring that each item is accounted for throughout its lifecycle. Additionally, IIoT security protocols help maintain data integrity and protect sensitive information related to inventory and assets, reducing the risk of unauthorized access or tampering.

Applications of RFID in Manufacturing

RFID technology is widely applicable across various industrial environments, enhancing manufacturing and industrial processes.

Manufacturing and Production

RFID technology is increasingly utilized in manufacturing and production environments to streamline processes and improve overall efficiency. Key applications include:

- Work-in-Progress Tracking: RFID tags are used to monitor and manage work-in-progress items throughout the production cycle. By attaching RFID tags to each workpiece, manufacturers can track its status, location, and progress in real-time. This continuous visibility helps ensure that materials move efficiently through the production line, reducing delays and bottlenecks.

- Inventory Management: RFID technology facilitates precise inventory management by providing real-time data on stock levels and item locations. This enables manufacturers to maintain optimal inventory levels, avoid stockouts, and reduce excess inventory, ultimately lowering carrying costs and improving production scheduling.

- Just-in-Time (JIT) Delivery: RFID supports JIT manufacturing by enabling accurate and timely delivery of materials to the production floor. RFID systems can synchronize with supply chain logistics to ensure that materials arrive precisely when needed, minimizing storage requirements and reducing lead times.

- Quality Control and Process Monitoring: RFID tags can store critical information about each product, such as batch numbers, manufacturing dates, and quality control data. This information helps ensure that products meet quality standards and allows for better traceability in the event of a recall or quality issue.

- Equipment Maintenance: RFID can be used to track the usage and maintenance history of machinery and tools. By monitoring equipment performance and maintenance schedules, manufacturers can perform predictive maintenance, reduce downtime, and extend the lifespan of their assets.

Our RFID Products for Manufacturing

To fully harness the benefits of Industrial IoT, having the right RFID technology is essential. Our company specializes in manufacturing high-quality passive RFID tags designed specifically for industrial applications. Our RFID tag products are engineered to deliver exceptional performance, even in challenging environments such as those with high metal interference or exposure to moisture. With a wide range of form factors and frequencies, our RFID tags are tailored to meet the diverse needs of industries like manufacturing, logistics, transportation, and more. By integrating our RFID tags into your operations, you can achieve enhanced visibility, optimize asset management, and drive operational efficiency across your entire enterprise.

ABS RFID Coin Token Tag

Plastic Housing On Metal RFID Tag

Epoxy RFID Mini Tag

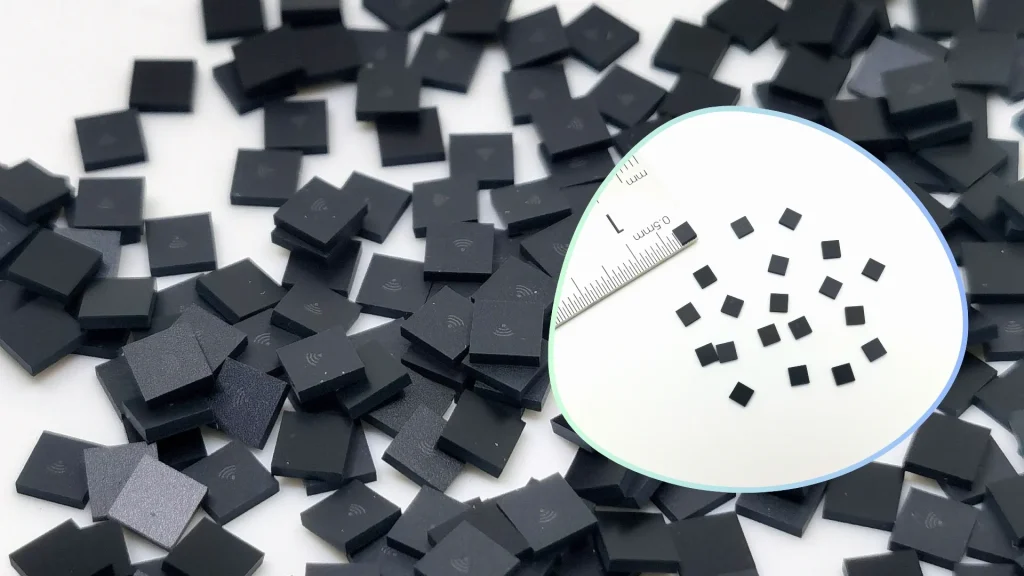

TMC UHF Micro Cube Tag

RFID AGV Navigation Position Tag

UHF RFID Ceramic Tag

Ready to Optimize Your Operations?

Take the next step towards transforming your industrial operations with advanced RFID technology. Contact us today to learn more about our RFID tag solutions and how they can be tailored to meet your specific needs. Let us help you drive efficiency, enhance visibility, and achieve better results in your business.