RFID for Logistics

As logistics operations become more complex and demand for real-time visibility increases, RFID for logistics is playing an increasingly important role in helping businesses streamline operations, enhance tracking, and make more informed decisions.

Unlike traditional barcode systems, RFID (Radio Frequency Identification) enables wireless data capture without the need for direct line-of-sight. With passive RFID tags embedded in goods, packaging, or logistics assets, companies can monitor the movement of items with greater efficiency. From warehouses and transportation hubs to last-mile delivery, RFID technology provides a flexible, automated method to support end-to-end logistics visibility.

RFID in Logistics Applications

Returnable Transport Packaging (RTP)

Managing reusable assets like pallets, crates, and bins has long been a challenge in logistics. RFID tagging of Returnable Transport Packaging (RTP) can help companies gain improved oversight over these resources. RFID allows organizations to record the movement of these units throughout the supply chain—from distribution centers to end customers and back again.

This level of tracking can help reduce loss rates, improve turnaround times, and support more accurate inventory replenishment. Over time, the insights gathered through RFID can contribute to more sustainable resource usage and help businesses make data-informed decisions regarding asset circulation.

Enhancing Pallet Management with RFID Technology

Warehouse Inventory Management

Effective inventory management is central to smooth logistics operations, and RFID offers a practical solution for improving warehouse visibility. By tagging products, pallets, or storage units with RFID tags, businesses can automatically track inventory levels and item locations in real time.

In warehouse and distribution center environments, RFID helps reduce labor-intensive inventory checks and minimizes errors caused by manual entry. This allows for faster stock reconciliation, easier identification of misplaced items, and more accurate stock counts. As a result, warehouse teams can improve order readiness, maintain optimal stock levels, and reduce delays caused by inaccurate inventory data.

RFID systems also support better space utilization by providing insights into inventory movement patterns, enabling more efficient shelving and picking strategies. Over time, this contributes to smoother warehouse workflows and more agile response to supply chain changes.

Yard and Dock Management

RFID also plays a growing role in yard management, where it supports tracking of trailers, containers, and vehicle movements within warehouse or distribution center grounds. Passive RFID tags attached to mobile assets, paired with fixed RFID readers at checkpoints, provide useful data about asset location, dwell time, and traffic patterns.

This data can assist logistics teams in improving gate management, sequencing trailer movements more effectively, and minimizing congestion during peak operational hours. Although implementation may vary depending on facility layout and infrastructure, RFID can contribute to incremental gains in throughput and visibility.

Last-Mile Delivery

For many logistics providers, the last mile remains the most challenging and cost-intensive part of delivery. RFID labeling of packages, containers, or even delivery vehicles can provide better insights into delivery status and routing. This can help logistics teams respond more quickly to exceptions or delays and make routing adjustments as needed.

Additionally, RFID-powered solutions facilitate seamless proof of delivery through automated scans, reducing the need for manual confirmation or signature collection. Customers benefit from more reliable delivery status updates, while businesses can streamline operations and reduce the potential for disputes.

UHF RFID Tag for Postal and Logistics

Benefits of Using RFID for Logistics

1. Enhanced Tracking and Visibility

RFID enhances the ability to monitor inventory and assets throughout the logistics journey. This includes location updates, transit conditions, and chain-of-custody tracking. Depending on the system design, RFID can help businesses identify bottlenecks and improve overall supply chain transparency.

2. Increased Operational Efficiency

By automating data collection, RFID can reduce the time spent on routine tasks such as scanning barcodes or manually entering inventory numbers. These efficiencies may translate to faster processing, reduced labor requirements, and fewer errors. This can free up resources and support faster, more scalable logistics operations.

3. Improved Inventory Accuracy

Real-time data from RFID systems supports more accurate inventory counts and helps minimize common issues like misplaced items or misaligned stock records. Over time, this can contribute to better inventory planning, optimized stock levels, and stronger supply chain resilience.

4. Cost Control Opportunities

While RFID implementation involves upfront investment, the long-term savings from reduced errors, improved asset control, and labor optimization can offset costs. RFID also helps lower the risk of asset loss and contributes to better utilization of returnable packaging and warehouse space.

5. Support for Sustainability Goals

Businesses looking to improve their environmental impact may find that RFID supports sustainable logistics. By reducing excess inventory, improving asset reuse, and optimizing delivery routes, RFID can indirectly contribute to lower emissions and more resource-efficient operations.

Recommended RFID Tags for Logistics Applications

As a company specializing in RFID tag manufacturing, we offer a comprehensive range of products—spanning flexible RFID labels, industrial-grade rugged RFID tags, and customizable RFID tags with various chip types and sizes—designed to meet the diverse needs of logistics applications.

Whether you’re operating in warehouses, transportation hubs, or last-mile delivery networks, we deliver reliable and stable RFID tag solutions that integrate seamlessly into your existing logistics infrastructure.

Hard RFID Tags (UHF)

- Ideal for: Reusable assets such as pallets, crates, and bins

- Features: Shock-resistant, waterproof, and dustproof

- Benefits: Durable and long-lasting, perfect for harsh environments and use in Returnable Transport Packaging (RTP)

Paper-Based RFID Labels

- Ideal for: Warehouse management, order fulfillment, sorting, packing, and last-mile delivery

- Features: Cost-effective, flexible application to cartons, plastic packaging, or product surfaces

- Benefits: Easy to print and apply; well-suited for large-scale item tracking and disposable packaging

Anti-Metal & Vehicle Identification Tags

- Ideal for: Containers, trailers, metal shelving, and yard equipment (Yard Management applications)

- Features: Anti-interference design, engineered for metal surface mounting

- Benefits: Maintains reading accuracy in metal-rich environments; improves tracking of vehicles and high-value transport assets

Explore our RFID tags for logistics and supply chain:

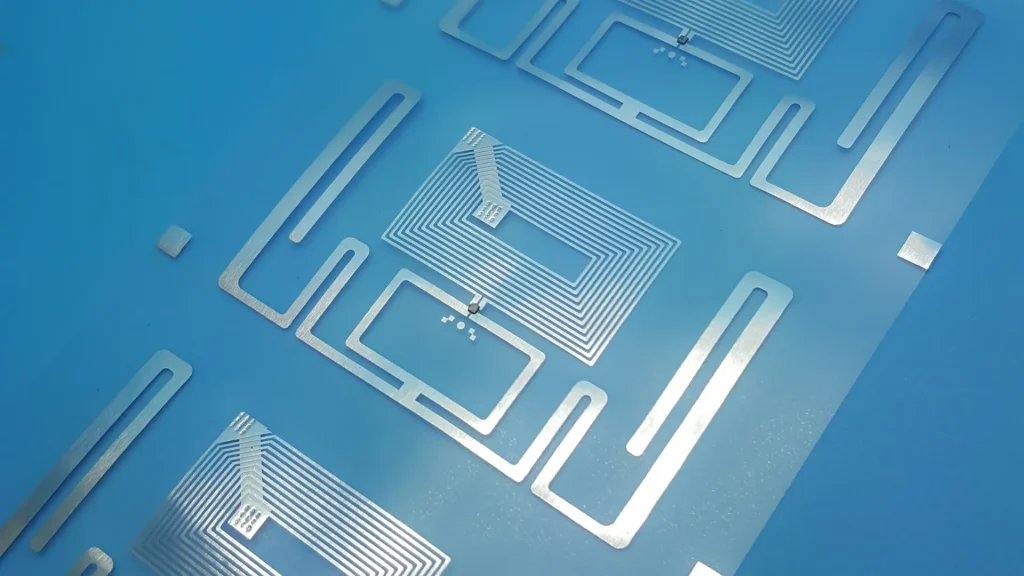

RFID Inlays

LogiFlex UHF RFID Pallet Tag

Versatile RFID UHF Tag

Flexible On Metal RFID Tag

Plastic Housing On Metal RFID Tag

Partner with a Trusted RFID Tag Manufacturer

RFID technology continues to unlock new possibilities for logistics performance. Whether you’re looking to optimize warehouse operations, gain real-time visibility over returnable assets, or streamline delivery workflows, the right RFID tags can make a measurable difference.

As a trusted RFID tag supplier, we’re committed to providing high-quality, reliable RFID tags that integrate smoothly into your logistics infrastructure.

Get in touch today to discuss your logistics challenges and find the RFID tag solution that fits your goals.